Whether you’re just getting started with print-on-demand (POD) or looking to enhance your product offerings, this guide covers the POD decoration methods offered on OMG online stores*, which decoration methods work best on various products and materials, and how to prepare your artwork files for the best results.

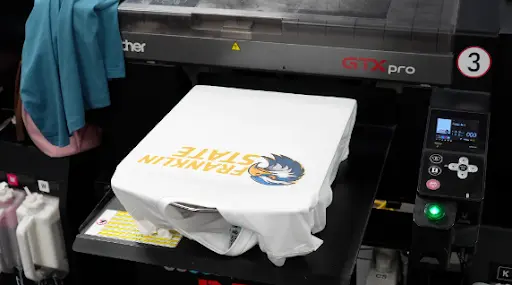

Direct To Garment (DTG)

Direct-to-garment, or DTG, is a decoration method that sprays water based ink directly onto the garment. The ink then soaks into the fibers of the garment and cures with the assistance of a pretreat. It is similar to printing on paper, but on fabric.

Preparing your art for DTG:

Your file should be at least 300dpi with a minimum line weight of 1. Formatted as either .png .svg .ai .eps .pdf .psd, .tif, .tiff.

- Best for: Apparel, tote bags, and more

- When to use: Photo realistic prints on cotton-rich apparel; doesn’t perform well on polyester or blends (colors fade) & not great for customers who have vibrant artwork or logos

- Pros: Photo-quality detail, great hand feel

Recommendation:

Since the ink is water based, 100% cotton garments are recommended. However, there are some blends within our POD catalog which have been tested and approved.

Direct To Film (DTF)

Direct-To-Film, or DTF, is a decoration method where the ink is applied to a piece of film vs directly onto the fabric. This pre-printed film is adhered to the garment through heat and pressure from a heat-press machine.

Preparing your art for DTF:

Your file should be at least 300dpi with a minimum line weight of 1. Formatted as either .png .svg .ai .eps .pdf .psd, .tif, .tiff

- Best for: Apparel, accessories, bags, and headwear

- When to use: Full-color logos, athleticwear/performance fabrics

- Pros: Vibrant colors, applies to many fabrics, durable

Recommendation:

Unlike DTG, you do not have the same fabric restrictions. This means you can utilize the DTF on-demand decoration with blended and polyester garments.

✅ Quick Compare: DTG vs DTF

DTG gives a softer, more natural feel that blends into the fabric– ideal for fashion-style tees with detailed images on cotton. DTF tends to be bolder and more versatile across fabrics preferred for bright designs.

We do not guarantee color output between DTG and DTF due to the color output.

Embroidery

Embroidery is a popular decoration method where a machine uses a needle and thread to stitch a design and logos to hats, polos, hoodies, and more. This method has grown in popularity within the print-on-demand market as a go-to method to provide customers with high-quality decoration.

- Best for: Apparel, accessories, bags, and headwear

- When to use: High-end or professional look

- When not to use: Less ideal for small text or complex logos with gradients or photos, Requires DST File

- Pros: Durable, high perceived value

Preparing your art for Embroidery:

- Your file must be digitized in .dst format prior to starting your order. When selecting a file for embroidery, you should eliminate any small details or fonts which may be unable to translate when sewn out.

- Embroidery requires a DST file. If you do not already have a digitizer, we recommend Forever Digitizing, Cre8tiveSkil, and Vitor Digitizing.

- Ensure your file has a minimum font size of .20″ on all lettering. This allows for the stitch to be clean on most materials depending on densities and the designs digitization. In addition, all details within a design should be larger than 1.75mm wide.

- If you have concerns over the quality of your file for embroidery, we recommend consulting with your digitizer.

Fulfill Engine supports threads as PMS matches. View the Fulfill Engine Network offering here. More colors can be accommodated after a review process. Please contact info@fulfillengine.com for any requests.

Laser Engraving

Laser Engraving is a decoration method where the laser acts as a chisel, incising marks by removing layers from the surface of the material. The laser hits localized areas with massive levels of energy to generate the high heat required for vaporization.

Preparing your art for Laser Engraving:

Laser Engraving does restrict your art to be formatted as 1 color (black)

- Best for: Drinkware, hard goods

- When to use: Tumblers, bottles, hard promotional items

- UV: Full color logos

- Engraving: Single color images

- Pros: Permanent, premium branding

Recommendation:

Popular products to engrave would be drinkware, cutting boards, and other accessories.

UV Direct-to-Film (UV DTF)

UV Direct-to-Film (UV DTF) is a digital printing technique that uses a UV printer to create a sticker-like transfer that can be applied to a variety of surfaces where a UV printer prints an image onto a release film using UV-curable ink. The printed image is then transferred from the film to a substrate using an adhesive backing.

Preparing your art for UV DTF:

- Your file should be at least 300dpi.

- Designs with thin isolated lines that are not on top of a background may have excess clear material showing around them in order to create enough surface area to stick properly to the item.

[New] LIQUID 3D™

Exclusive to Fulfill Engine, LIQUID 3D™ redefines dimensional emblems and unlocks on-demand decoration without costly setups or minimum quantity requirements. This innovative patent-pending technology from STAHLS’ combines high-definition, full color 3D printing with versatile finishes and textures that make any logo look and feel like nothing else.

- Best for: Headwear and bags

- When to use: Dimensional branding on flexible surfaces

- Pros: Bold, high-end aesthetic, unique decoration (think PVC patch without color limitations or quantity minimums with the ability to add texture to the surface)

Preparing your art for LIQUID 3D:

Your file must be a vector .pdf format to upload successfully in the real-time LIQUID 3D artwork builder. To learn more, click here.

Have additional questions? Check out the Fulfill Engine Help Center for other related articles or contact the Fulfill Engine team at info@fulfillengine.com for decoration or artwork-specific inquiries.

*Print-on-demand is currently only available on our Pop-up Store solution